When it comes to efficient water management, selecting the right equipment is crucial, and one of the standout choices in this domain is the submersible pump. These versatile devices are designed to operate underwater, making them ideal for a range of applications, from residential drainage to commercial pumping solutions. Their ability to handle various types of fluids, coupled with their energy efficiency, positions submersible pumps as essential tools for those looking to tackle water-related challenges effectively.

In this article, we will explore the top 10 submersible pumps available on the market today. Each model offers unique features and benefits tailored to different water management needs, ensuring that there is an optimal choice for every scenario. Whether you are dealing with excess water in your basement, managing irrigation systems, or providing water supply in industrial settings, understanding the capabilities and specifications of these pumps can help you make informed decisions. Join us as we dive into the best submersible pump models, highlighting their effectiveness, ease of use, and reliability for all your water management requirements.

Submersible pumps are integral to various water management applications, functioning efficiently beneath the water's surface. These pumps operate by utilizing a motor that is hermetically sealed, allowing it to be submerged in fluids without suffering damage. When activated, the motor drives an impeller, which pressurizes the water, pushing it to the surface through a discharge line. This design not only makes submersible pumps more effective at handling larger volumes of water but also minimizes the risk of cavitation, a common issue in traditional pumps that can lead to equipment wear and failure.

Industry reports indicate that the global submersible pumps market is projected to grow at a compound annual growth rate (CAGR) of approximately 4.3% from 2021 to 2026, driven by their increasing application in municipal water systems, irrigation, and sewage treatment. The versatility of submersible pumps is particularly useful in sectors such as construction, where they manage groundwater levels during excavation, or in the oil and gas industry for degassing applications. As water scarcity becomes an increasingly pressing issue, the role of efficient water management technologies, including submersible pumps, will only continue to expand, providing sustainable solutions for industries around the world.

Moreover, submersible pumps are designed for a variety of fluids, from clean water to more abrasive liquids, making them ideal for diverse applications. They can handle both vertical and horizontal installations, further enhancing their adaptability in different environments. With advances in materials and technology, modern submersible pumps offer improved reliability and energy efficiency, key factors that contribute to their growing adoption in both residential and industrial settings.

When selecting a submersible pump, one of the primary considerations is the pump's intended application. Different pumps are designed for specific tasks, such as draining basements, managing stormwater, or facilitating agricultural irrigation. Understanding the specific requirements of your water management task will help narrow down your options. Additionally, consider the total dynamic head (TDH), which indicates how high the pump can lift water. A pump with appropriate TDH for your application ensures efficient performance without overstraining the motor.

Another key factor is the pump's material construction. Submersible pumps are exposed to water and possibly abrasive particles, so durability is essential. Pumps made from high-quality materials such as stainless steel or thermoplastic can provide increased longevity, especially in challenging environments. In addition, pay attention to the motor type, whether it is submersible or external, as this can affect installation flexibility and maintenance requirements. Finally, check the power source options available to ensure compatibility with your setup, as some pumps operate using electricity, while others might use gasoline or solar power, depending on your needs and location.

When it comes to managing water effectively, submersible pumps are indispensable tools across various applications, from residential water features to industrial drainage systems. These pumps are designed to operate underwater, making them ideal for removing water from basements, irrigation purposes, and even dewatering mines. A comprehensive review of leading models reveals the importance of considering factors such as pump material, power, flow rate, and motor type when selecting the right submersible pump for specific needs.

High-quality submersible pumps typically feature durable constructions that can withstand the conditions they are placed in, including exposure to harsh chemicals or sediments. The selection of the impeller design and the motor power directly affects the efficiency and longevity of the pump. Additionally, noise level and energy consumption are also key considerations, particularly for applications where the pump will be in use for extended periods. By evaluating these factors alongside the performance ratings of different models, users can ensure they choose the most suitable submersible pump to meet their water management requirements.

| Model | Power (HP) | Flow Rate (GPM) | Max Head (feet) | Weight (lbs) | Material |

|---|---|---|---|---|---|

| Model A | 1.5 HP | 50 GPM | 40 feet | 45 lbs | Stainless Steel |

| Model B | 1 HP | 30 GPM | 35 feet | 38 lbs | Plastic |

| Model C | 2 HP | 70 GPM | 50 feet | 50 lbs | Cast Iron |

| Model D | 0.5 HP | 20 GPM | 25 feet | 25 lbs | Aluminum |

| Model E | 3 HP | 90 GPM | 60 feet | 60 lbs | Stainless Steel |

| Model F | 2.5 HP | 80 GPM | 55 feet | 55 lbs | Cast Iron |

| Model G | 1.2 HP | 35 GPM | 30 feet | 40 lbs | Plastic |

| Model H | 0.75 HP | 25 GPM | 22 feet | 20 lbs | Aluminum |

| Model I | 4 HP | 100 GPM | 65 feet | 70 lbs | Stainless Steel |

| Model J | 1.8 HP | 60 GPM | 45 feet | 48 lbs | Cast Iron |

| Model K | 1.5 HP | 55 GPM | 42 feet | 42 lbs | Plastic |

Proper maintenance is essential for maximizing the lifespan of your submersible pump and ensuring its efficient operation. Regularly inspecting the pump for any signs of wear or damage is crucial. This includes checking for leaks, unusual noises, or vibrations that may indicate mechanical issues. Keeping the pump clean and free from debris will also help maintain optimal performance, as blockages can lead to overheating and eventual failure.

Another important aspect of pump maintenance is monitoring the operating conditions. Ensure that the pump is suited for the specific environment and application. For instance, pay attention to the temperature and chemical composition of the water it is moving. Running a pump under inappropriate conditions can significantly shorten its lifespan. Additionally, consider implementing a schedule for routine oil changes or seal replacements, as these practices can prevent premature wear and extend the overall functionality of your pump. Regular maintenance not only enhances performance but also reduces the likelihood of unexpected breakdowns, saving both time and money in the long run.

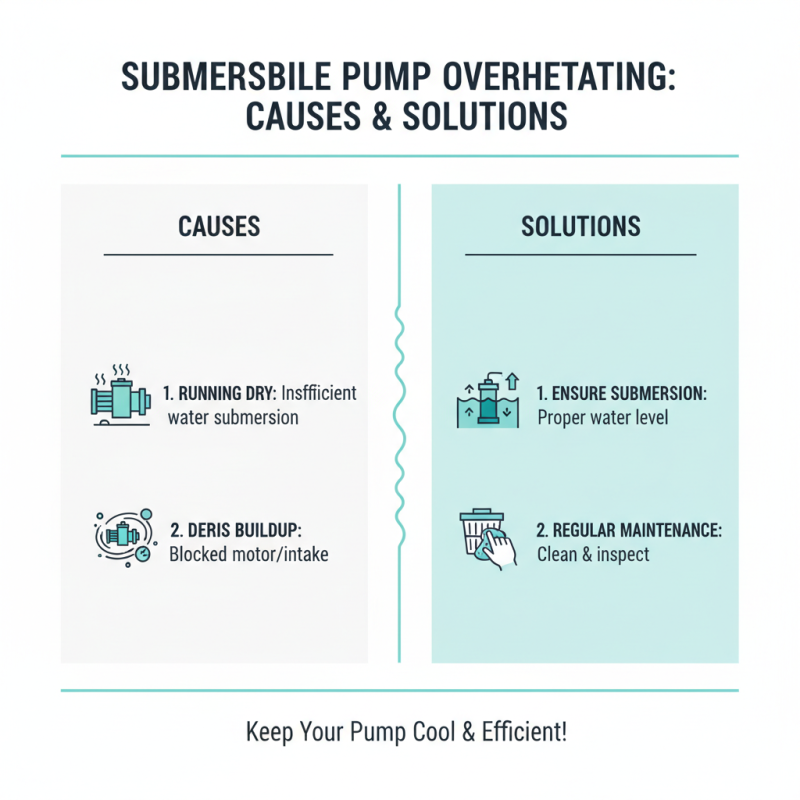

Submersible pumps play a crucial role in various water management applications, but they are not without their challenges. One common issue is overheating, which can occur if the pump is running dry or if there’s a significant buildup of debris around the motor. To troubleshoot this problem, ensure the pump is submerged in water and inspect the surrounding area for any obstructions. Regular maintenance, including cleaning and checking for wear and tear, can also help prevent overheating.

Another frequent problem faced by users is a decrease in pumping efficiency, often indicated by unusual sounds or reduced water flow. This may be caused by a clog in the intake or a malfunctioning impeller. To address this, first check the intake screen for blockages and clear any debris. If the impeller is damaged, it may need to be replaced. Additionally, ensure that the power supply to the pump is stable and that proper voltage levels are maintained, as fluctuations can affect pump performance significantly. Regular inspections and prompt repairs are essential to keep your submersible pump operating optimally.

Please enter the details to download, thank you

Get in Touch With Us

Please enter the details to download, thank you

Please enter the details to download, thank you

Please enter the details to download, thank you

Please enter the details to download, thank you

Please enter the details to download, thank you

Please enter the details to download, thank you

Please enter the details to download, thank you

Please enter the details to download, thank you

Please enter the details to download, thank you

Please enter the details to download, thank you

Please enter the details to download, thank you

Please enter the details to download, thank you

Please enter the details to download, thank you

Please enter the details to download, thank you

Please enter the details to download, thank you

Please enter the details to download, thank you

Please enter the details to download, thank you

Please enter the details to download, thank you

Please enter the details to download, thank you

Please enter the details to download, thank you

Please enter the details to download, thank you

Please enter the details to download, thank you

Please enter the details to download, thank you

Please enter the details to download, thank you

Please enter the details to download, thank you

Please enter the details to download, thank you

Please enter the details to download, thank you

Please enter the details to download, thank you

Please enter the details to download, thank you

Please enter the details to download, thank you

Please enter the details to download, thank you

Please enter the details to download, thank you

Please enter the details to download, thank you

Please enter the details to download, thank you

Please enter the details to download, thank you

Please enter the details to download, thank you

Please enter the details to download, thank you

Please enter the details to download, thank you

Please enter the details to download, thank you

Please enter the details to download, thank you

Please enter the details to download, thank you

Please enter the details to download, thank you

Please enter the details to download, thank you

Please enter the details to download, thank you

Please enter the details to download, thank you

Please enter the details to download, thank you